Fixing Dead Pixel Lines on a GB

The Problem

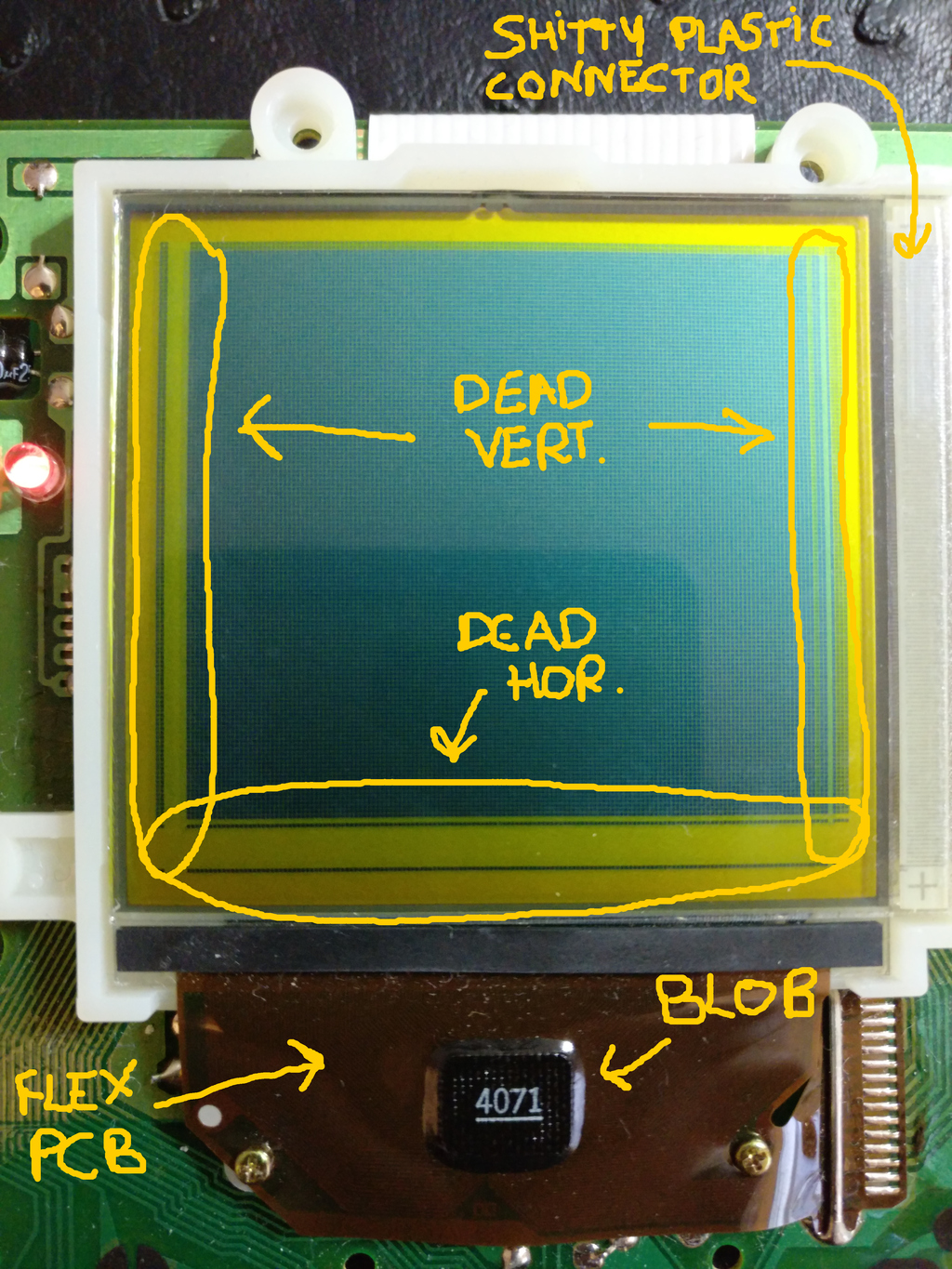

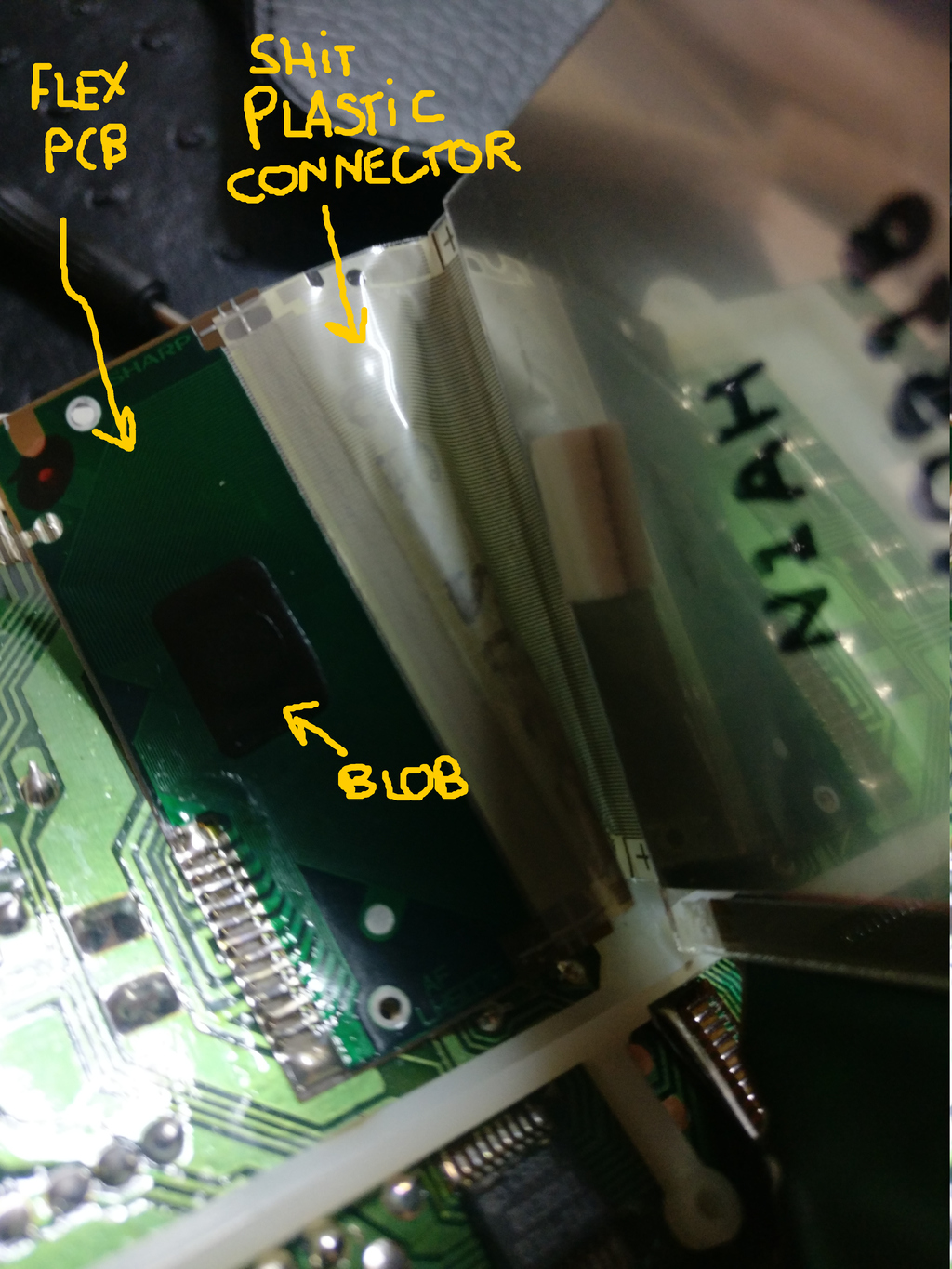

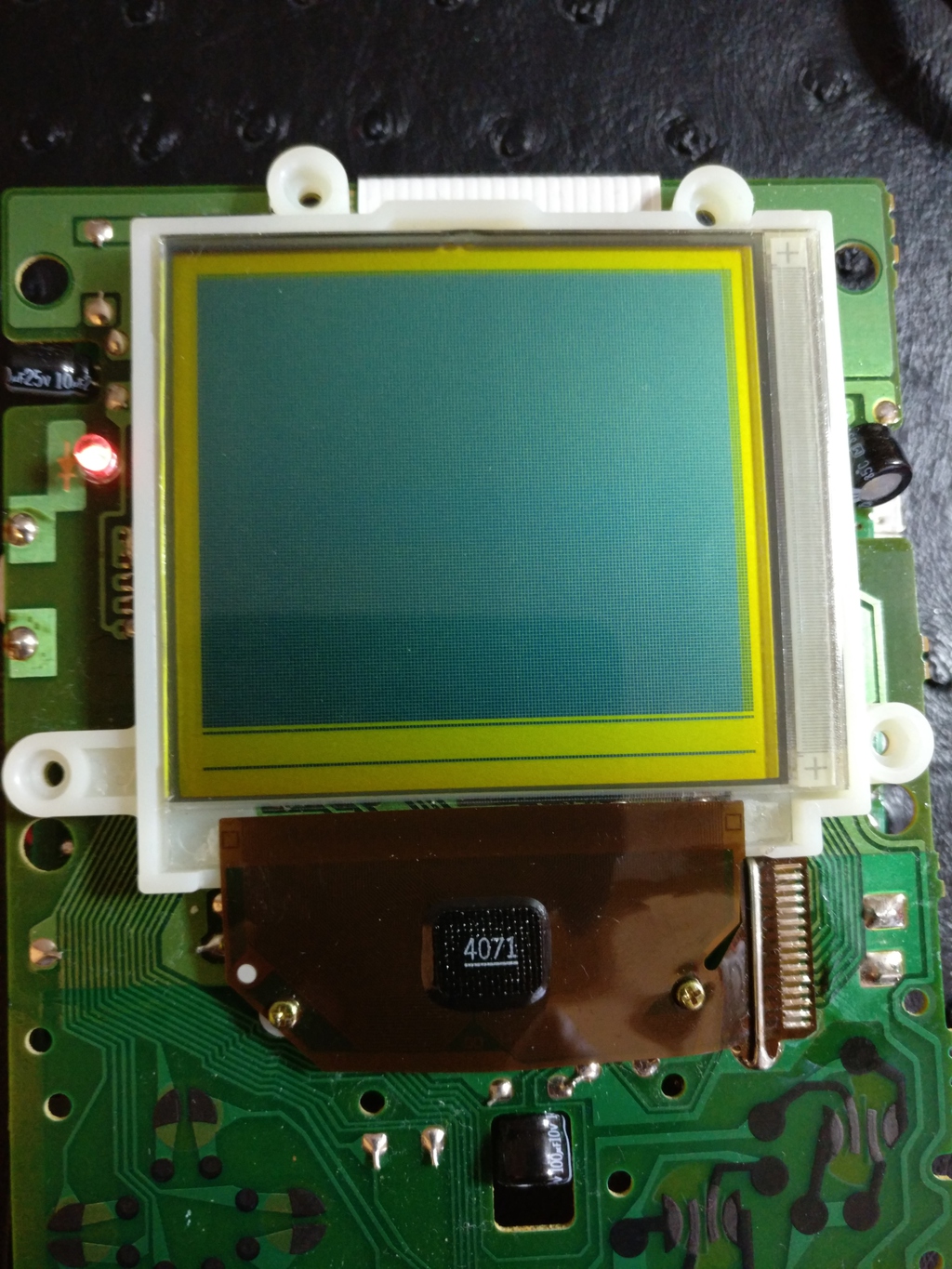

The LCD screen is driven by two chips hidden in epoxy blobs: one in the front of the LCD, and the other in the back. Blob 1 (controls vertical lines) is connected to the screen with a flexible PCB, while blob 2 (controls horizontal lines) is connected to the screen via both a flexible PCB and a super flimsy plastic sheet that hold some of the traces. With time, some of the traces can be damaged and/or the connections get a little bit loose. This leads to sudden loss of pixel rows and columns. Applying heat to some parts can help somehow reflow some connections and therefore bring theses dead pixel lines back to life.

The Fix

Fixing Vertical lines

Fixing the vertical lines requires patience, but is usually quite straightforward:

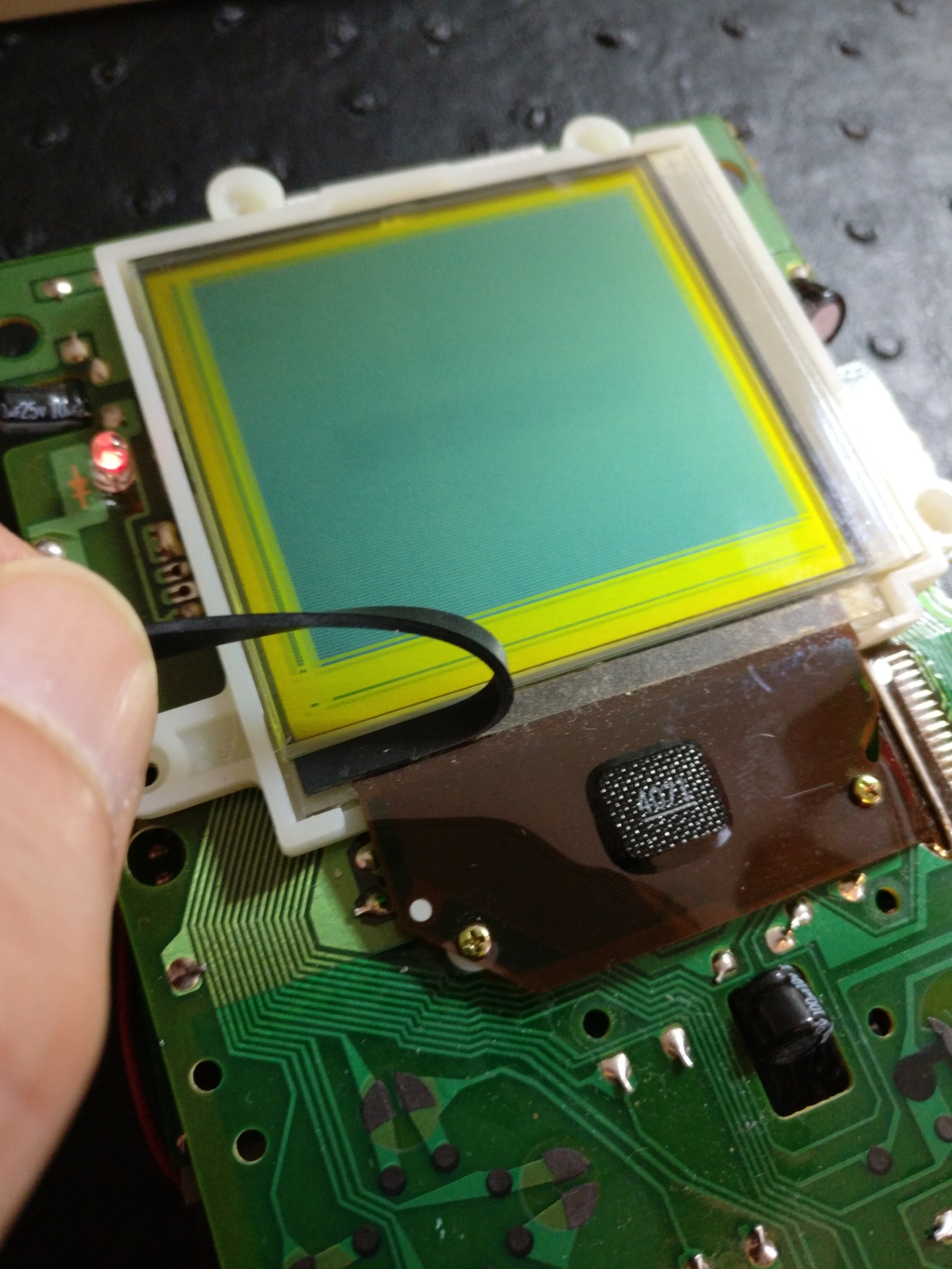

- First peal the rubber spacer from the front flexible PCB, don't forget to also remove/scrub the little tape below that helps making it stay in place. Don't worry you can toss it, the rubber can stay in place fine afterwards, without this tape.

- Use a temperature controlled soldering iron with a relatively flat/large tip. You could get away using a regular soldering iron with a thin/pointy tip, but this is going to drastically increase the chance of destroying the flex PCB. It can take quite some heat, but better not push your luck.

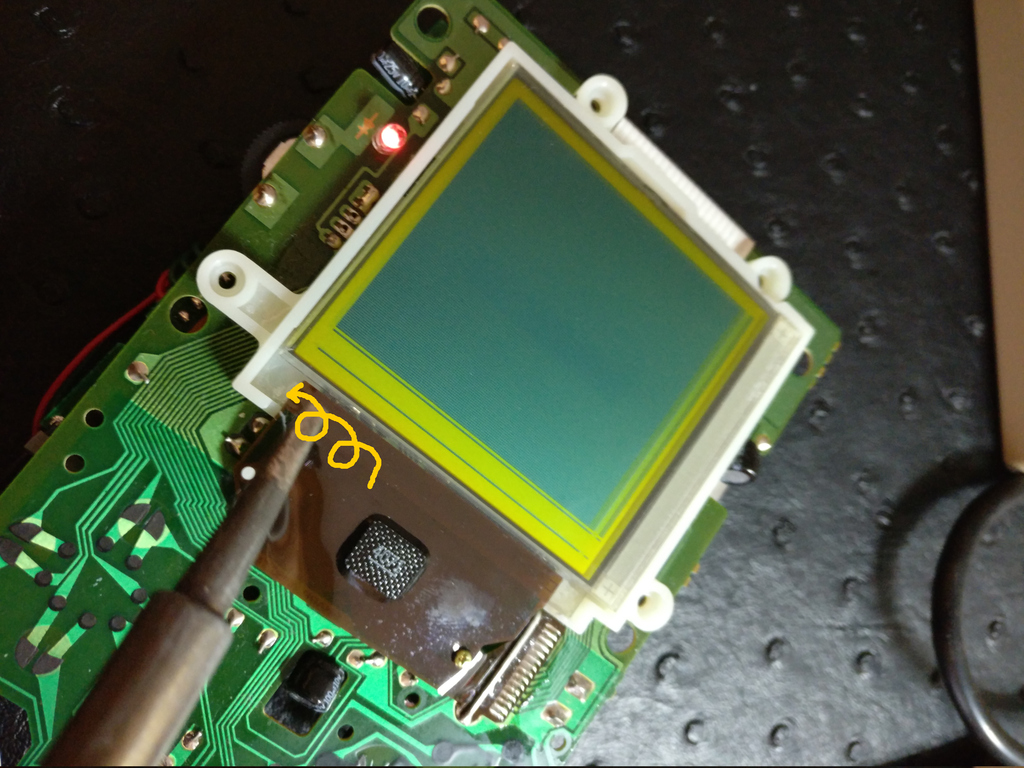

- Start at 220 degrees C. Gently circle the tip of the soldering iron below the screen, on the flexible PCB. Don't stay in contact for more than 2-3 seconds, let it cool, repeat. Eventually you will start to see some lines flicker, some working ones will stop working, some non-working ones will start working, don't panic, keep on doing that, find what patterns make them appear/disappear. Usually they all come back. Most lines are fine with such relatively low temperature, but if some are really not coming back, don't hesitate to go up to 280 degrees C.

- DON'T RUSH IT, IT CAN TAKE A LONG TIME. Eventually they should all work back nicely, and you will be good for a couple more years :) Obviously, and sadly, sometimes some vertical lines can never be fixed, it's not super rare to encounter such a case, but it is pretty uncommon if you do things properly.

Fixing Horizontal Lines

In theory fixing horizontal lines is the same as with fixing vertical lines, but there are three problems. First, the flexible circuit is being the LCD screen. Second, only a small part of the wiring is done as a flexible circuit, most of the LCD connection is done via a much more fragile plastic layer that guides all the traces. Third, it's not always clear where the damage is located, making the whole process less predictable.

If you're lucky, then the problem lies on the rail that's on the right of the screen. Set your soldering iron to 150-200 degrees C, and try slide it up and down the rail, gently, letting it cool from time to time. Remember it's plain plastic it can't take much heat or it will melt and break all the traces. If that does not work you can try to lift the LCD screen (unscrew the flexible circuit in the front, and gently lift the LCD), and try to heat the back flexible circuit (same instructions as for horizontal lines fix). Careful though if your soldering iron hit the plastic sheet that bridge the flexible circuit and the LCD panel, it's game over. If this still does not work, as a last resort, try to heat (100-120 degrees C max) this very infamous plastic layering.

If it does not work, or if you manage to make things worse, don't despair, there is a reason why people tend to stay clear from fixing screens with such a defect: it rarely ends up with a happy ending, and even if you manage to fix a few horizontal lines, it's often that some may be stuck forever, specially if your screen was suffering from a whole horizontal block missing, as opposed to one single lines being off.

Here is a nice blog post from nitro2k01 about the problem with fixing horizontal lines.